Customer Background

Ms. Duangkamon from a logistics and warehousing solutions company in Thailand reached out to us on September 20, 2024, inquiring about explosion-proof goods lifts for their end customer. Given their industry’s safety requirements, she needed a reliable and certified solution for lifting goods.

Requirements

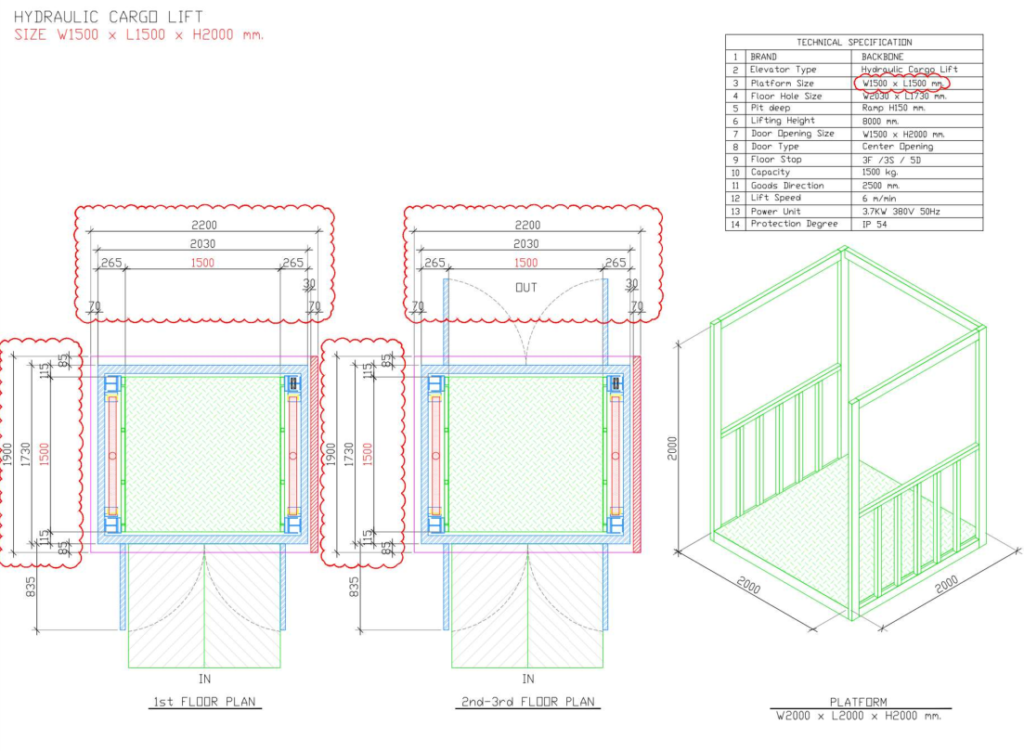

Ms. Duangkamon’s company needed explosion-proof goods lift with the following key requirements:

- Load capacity: 1500kg.

- Platform size: W1500mm × D1500mm.

- Lifting height: 8000mm.

- Stops: Three

- Entry/exit configuration: Single-sided on the 1st floor; 180° through-opening on the 2nd and 3rd floors.

- Explosion-proof components, including:

- Explosion-proof motor: BT4-rated (ABB or equivalent brand)

- Control system: CT6-rated

- Electrical box: CT6-rated

- Hydraulic oil pipes: Galvanized for added durability

- Emergency safety features for operational security

To further assist in her decision-making, we sent a video showing the explosion-proof components of a similar product we had recently manufactured. The video demonstrated the high-quality materials and the safety features of our goods lift.

The following documents had been submitted to SGS inspectors to review.

| No. | Documentation | Specification | Result | 1 | EX proof certificate | GB standard | Conformity |

|---|

Design and Solution

Having completed similar explosion-proof lift projects before, we quickly responded with technical drawings and compliance documentation. To further support the customer’s decision-making, we provided a factory video showcasing the explosion-proof components and manufacturing process, demonstrating the high-quality materials and safety features of our lifts.

To ensure alignment with their needs, we conducted a video conference, allowing Ms. Duangkamon and her team to tour our factory virtually. During the meeting, we reviewed all technical details to confirm that the solution met their specific requirements.

Challenges and Final Solution

During the process, we encountered a challenge regarding the required lift dimensions. The customer provided strict specifications, but our standard materials led to a slight deviation in the mesh guard size. To resolve this, our engineering team redesigned the structure, replacing 125H steel with reinforced 100H steel. This ensured both structural stability and compliance with the customer’s space constraints.

Additionally, after an initial quotation, we adjusted the pricing to include a protective mesh guard based on customer feedback. We also provided proof of explosion-proof certifications, including those for the control system and motor, to address their safety concerns.

Final Outcome

By February 2025, after multiple rounds of negotiation, technical confirmations, and certification verifications, the customer finalized the order. To further assure product reliability, we offered a two-year warranty. This successful transaction reinforced our expertise in delivering compliant, high-quality lifting solutions for hazardous environments.

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention to the email info@xyzlift.com

Or contact us by whatsapp +86-18366130656