Customer Background

Peter works for a smart intralogistics solutions company that is based in Sydney, Australia. The company specializes in mezzanine racks. In June 2020, they placed an order for 4 mezzanine goods lifts for their client. They provide their services to DHL, Toyota, IKEA, Unilever, etc. since they work with such big industry names, all the lifts must comply with the Australian standards. They must be registered with ‘SafeWork NSW.’ XYZlifts promised not only to provide lifts that comply with all regulations but also to provide affordable goods lift price.

Client Requirements

The client required 4 mezzanine goods lifts with up and down typical warehouse lift functions. Some of the specifications were:

- Australian standard pallet: 1165mm x 1165mm

- Maximum pallet weight: 1000kg

- Ground-level at 0 mm, First level at 3530mm, Second level at 7030mm

We were also required to provide detailed estimated prices of all the 4 lifts to the customer so they could make a final decision.

Our Design

We sent Peter the complete design specifications of the mezzanine goods lifts after consulting with our engineers. The lift will have three stops, with a platform size of 1.5*1.5m with a mesh cover. The following regulations were complied by as the lifts were to be installed in Australia:

- EN ISO 12100:2010 – (Safety of Machinery-Design Risk Assessment & Reduction)

- EN 81-31:2010(Safety rules for the construction and installation of lifts – Lifts for the transport of goods only)

- EN 60204-1:2006+A1:2009+AC:2010 (Safety of machinery-electrical equipment of machines)

During the filling of the ‘SafeWork NSW’ registration form, we provided the below-mentioned information to support the client.

– Electrcal diagrams and hydraulic circuit diagram

- The manufacturer provided certificates of the equipment used that include the ropes, hoses, control valves, etc.

- Brand details and specifications of the hydraulic cylinders.

- Pressure rating for the hoses and the valves. The client also required hoses and 3-way valves for local testing.

Drawing Communication

During the entire drawing process, the customer was deeply involved. The customer required lift as well as pit drawings. The client reserved the space between the racks to build a pit. Initially CAD drawings were shared with the client but since they are a little difficult to understand, we also shared 3D pit drawing with the client. XYZlifts always works in the better interest of the customer and that is why customer understanding is very important to us.

Installation

It was an urgent order; the client required all the 4 lifts as soon as possible. To save the client’s time, we pre-installed a lot of the parts and before the steel rust removal. In order to facilitate the client, we also made assembly and operational videos.

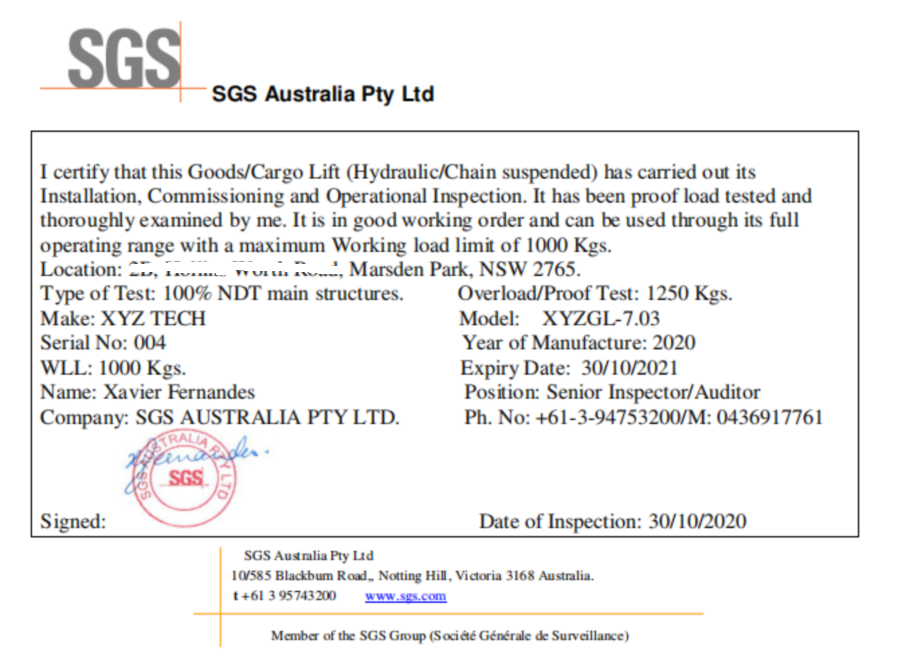

Approved by SGS Australia Pty Ltd

SGS, Australia tests the working and safety of the 4units lifts and provides certification and verification. An approval from SGS is the sign that the products and services are according to global standards.The verification from SGS Australia Pty Ltd. is identified as the national criterion for quality and perfection.

Customer Feedback

XYZlifts is definitely one brand that can be trusted as it is trusted by a lot of international brands and big names. This company knows the dynamics of the industry and know how to satisfy their clients. We usually purchase goods lift, and we will sure ask goods lift price again for other project.