Customer Background:

Azko Nobel Coating is a well-known coating company in Vietnam. It is a reliable paint company that is qualified in making an excellent coating. It has been providing coating services for more than two centuries. Famous brands like Dulux, Interpon, and Sikkens have partnered with the company in developing long-lasting paints. It has a coating plant and needed a set of explosion proof goods lifts for the warehouse for the safety of the staff.

Requirements:

The requirements for the anti-explosion goods lift were

- All parts of the goods lift should be explosion proof, well working at costing area.

- A cylinder with an over-loading pressure value, and a rupture valve.

- A lift where the platform would work smoothly and not sway.

- A device with a 28 months warranty.

- The travel height of the lift must be 10900mm.

- It should be able to carry a load of 3000kgs as the coating material will be transferred between 3 floors.

- The size of the installation site is 3950W*2900mmD, so the platform must be built according to it.

Design and Solution:

We designed the goods lift for coating industry quite efficiently. We utilized 150mm H steel for building the guide rails, which is better than any other regular steel.

We added the following features to make it explosion-proof.

- Explosion Tube Level C

- Limited Switch CT6

- Motor BT4

- Electric Box CT6

- Controller CT6

The lift was able to carry up to 3000kg easily, and the platform size was 3050*2500mm along with a mesh cover.

XYZLIFT built the explosion proof goods elevator for its customer by keeping in mind all the hazardous situations. The lift has the capacity to achieve high levels of safety in dangerous conditions. The explosion-proof can descend automatically without any assistance in case of a health emergency, fire eruption, or power shortages in the area. This explosion proof cargo lift is best to be used in the places like gas & oil refineries, chemical areas, and defense zones, etc.

An SGS inspection takes place before the shipment of the lift. Once the client approves the report, the lift is delivered.

The SGS inspection includes :

– Quantity Check

– Marking Check

– Visual quality Check

– Dimension Check

– Document Review

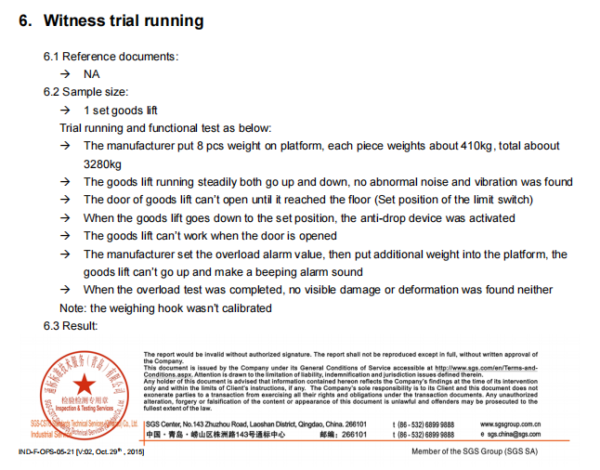

– Witness Trial Running

Customer Feedback

“The engineers at XYZTECH understood my requirements excellently and delivered the lifts according to them. We have purchased two sets, and the quality is top-notch. Both of the explosion proof goods lifts are certified by SGS. They provided a detailed explanation of how the lift works during the installation, which made it quite easy for us. We will keep on working with this company.”