How to choose cargo lift manufacturer

When it comes to finding the perfect warehouse cargo lift, the market offers numerous suppliers, making it challenging to determine which one is the best fit for your needs. In this comprehensive guide, we will walk you through the key factors to consider when purchasing a warehouse cargo lift. From understanding the materials used in construction to examining safety features and installation requirements, we aim to provide you with the knowledge necessary to make an informed decision. Our focus is on delivering valuable insights that cater to the needs of businesses like yours, ensuring that your warehouse operations run smoothly and efficiently.

1.Steel Material Selection for Warehouse Cargo Lift:

The choice of steel material plays a crucial role in the construction of a durable and reliable warehouse cargo lift. XYZLIFT purchase steel are all from China big and famouse brand steel company, comply with China standard.

Key components to consider include:

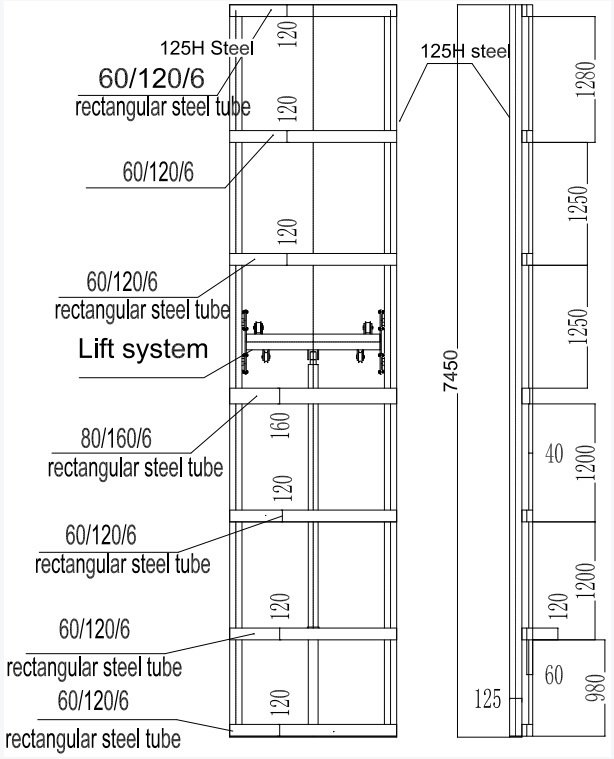

- Guardrail: Utilizing high-quality H steel, cargo lift load capacity less than 3000kg preferably 125#H steel, more than 3000kg choose 150 H steel, load capacity more than 5000kg use 175 H steel. ensures the guardrail’s verticality even after extended use.

- Guardrail Beams: Incorporating robust rectangular steel tube beams at a distance of 1.2m enhances the strength and stability of the guardrail. Near lifting system,we choose stronger rectangular steel tube. Below drawing showed the load 3000kg and lift height 5m cargo lift for your reference.

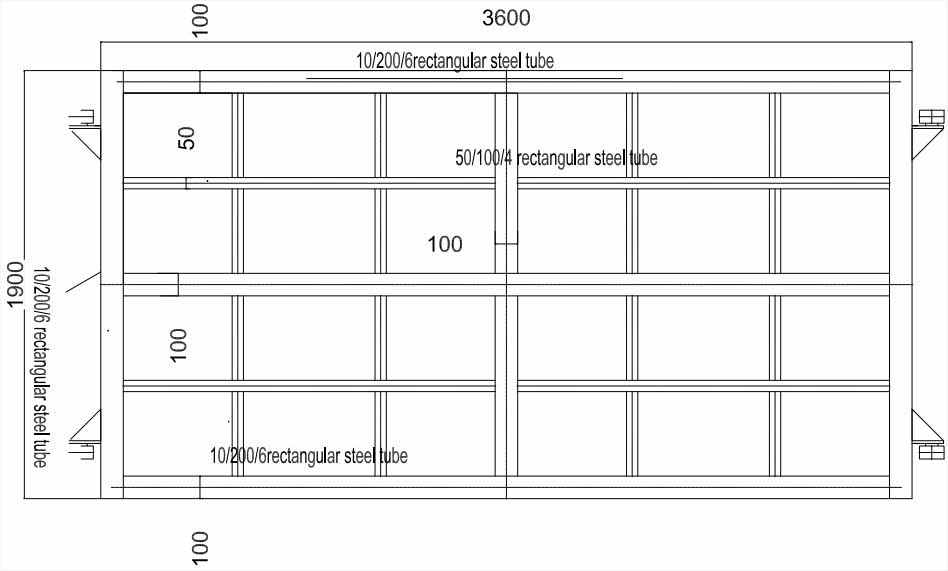

Platform: All platform surface are anti-skid plate, but under the anti-skid plate, it is the base. Base structure decide the load capacity. Before produce warehouse cargo lift, our engineer will calculate and choose right size rectangular steel tube and make drawing. Worker will produce platform accordingly.From cargo lift picture, we could not see the base structure, but it is the important factor. Below drawing is XYZLIFT cargo lift platform base drawing.

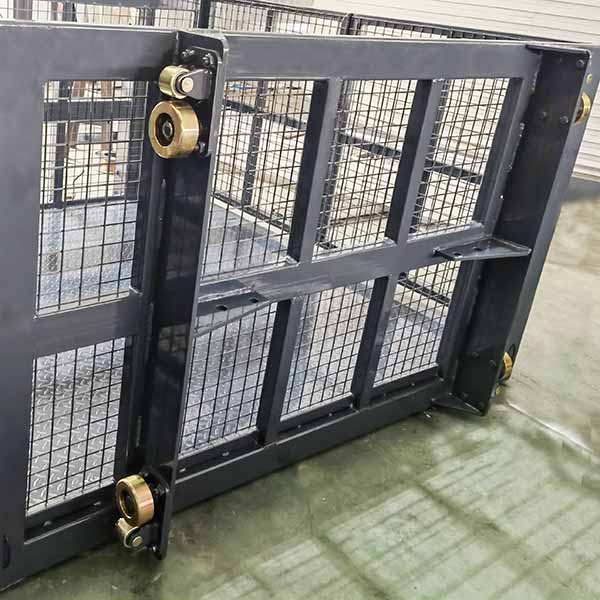

- Lift plate: Lift plate height and material use, we may not concern it, but as professional cargo lift manufacturer, we want to share with you, it is really important, because if lift stable is not stronger, the when lift working, lift platform may sway. And cargo lift sliding wheels are all galvanized.

2.Hydraulic motor pump station:

XYZLIFT choose motor is very strict, all most goods lift use Siemens hydraulic motor. After long time use, near no damaged. Motor is produced according to customer local voltage. Standard whare cargo lift is working under 3phase voltage,if at customer local site, there is no 3 phase voltage, only single phase voltage. We also have solution, use two single phase motor, it not only guarantee the lift speed, but also solve the no 3 phase voltage question. If choose economic kind cargo lift, we also could use China brand pump station. Some customer need higher quality cargo lift, choose SEW motor, XYZLIFT team also could do it. We supply hydraulic pump station cabin for cargo lift.

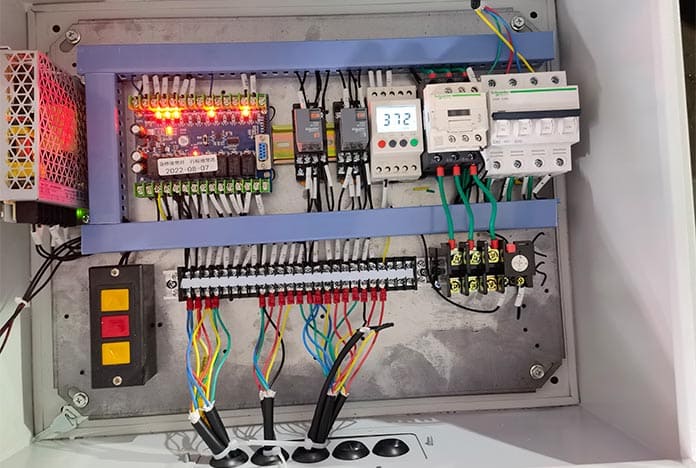

3.Electric box choose

Electric parts we use brand Schneider, we installed the switch key for electric box, do not use cargo lift,we could close the electric box power, prevent someone control lift. Voltage protection, if voltage is over or less than setting voltage, warehouse cargo lift will be stop work. Each wire with label, we will know the wire for which function.Control button for maintaince and installation cargo lift use. When installation site local voltage is single phase, we also install the frequency. And one important factor that all wire are connection well. We only fixed to the right postion after customer received cargo lift.

4.Hydraulic cylinder

Hydraulic cylinder size according to the warehouse cargo lift load capacity and lift height. Hydraulic cylinder is mounted the explosion proof valve, if the oil pipe and cylinder is damaged, lift will not down suddenly. Explosion proof valve will block the oil back to the pump station, so the platform will stop drop. When we confirm the warehouse cargo lift price,also confirm the cylinder size.

5.Warehouse cargo lift standrad safety

- Overload warning, if load capacity more than setting load, cargo lift will be stop working and warning.

- Platform door with interlock, door open lift do not work, only door closed, lift could work.

- Finial limited switch, final floor with 2 limited switch, if top floor level limit switch do not work, final limited switch will work. Double production function.All limited switch brand Omron.

- Emergency stop, each floor control panel with emergency button, include the electric box.

- Power switch key. Electric box with switch key, if do no use work, we could close the electric box power, prevent someone to control warehouse cargo lift.

- Emergency decline. We put the emergency decline valve out the pump station.If out power source, we could down platform by emergency decline valve.

- Mesh enclosed cargo lift, landing door with safety lock, not only landing door closed,and mesh enclosed cargo lift could work, but also cargo lift did not arrived floor level, lading door could not open.

- Hydraulic cylinder with the explosion valve,if hydraulic oi is damaged and leak oil, platform will lock and do not down suddenly.

6.Warehouse cargo lift bearing, bolt and wheels

We prioritize the longevity and smooth operation of our warehouse cargo lifts. That’s why we utilize galvanized bearings, bolts, and wheels throughout the lift’s construction. Here’s why this choice is crucial:

Rust Prevention: Galvanization is a process that involves coating metal components with a layer of zinc, providing effective rust prevention. By using galvanized bearings, bolts, and wheels, we ensure that our cargo lifts remain rust-free even with prolonged use. This not only extends the lifespan of the lift but also maintains its optimal performance.

Smooth Operation: Among these components, the bearings play a crucial role in the lifting system. When the lift is in operation, the lifting system slides along the guardrail. If the bearings were to rust, it could lead to increased noise and friction, affecting the smoothness of the lift’s operation. By using galvanized bearings, we eliminate the risk of rust-related issues, ensuring quiet and smooth performance over an extended period.

Attention to Detail: XYZLift emphasizes the importance of this factor to help you identify a reliable cargo lift manufacturer. By highlighting our use of galvanized components, we demonstrate our commitment to delivering high-quality, long-lasting products that operate seamlessly and provide a superior user experience.

By employing galvanized bearings, bolts, and wheels in our warehouse cargo lifts, XYZLift prioritizes the prevention of rust and guarantees a smooth and noise-free operation. These considerations contribute to the overall reliability and satisfaction you can expect from our cargo lift solutions.

7.Parts bending and cut

At XYZLift, we prioritize both the quality and aesthetics of our cargo lifts. To achieve this, we employ precision cutting techniques and pay close attention to the details of our lift components. Here’s how we ensure exceptional quality and a polished appearance:

Precision Cutting: Special parts of the cargo lift undergo cutting using state-of-the-art CNC (Computer Numerical Control) machines. This advanced technology ensures precise and accurate cuts, resulting in smoothly finished edges. Compared to traditional saw cutting methods, CNC cutting guarantees a superior fit and seamless integration with other parts.

Rust-Proof and Stainless Steel Components: The platform door hinge is carefully selected to be rust-proof, ensuring long-term functionality and durability. Additionally, the door itself is constructed using stainless steel, which not only enhances its resistance to rust but also adds an aesthetic touch to the cargo lift.

Surface and Edge Treatment: Standard parts of the cargo lift undergo meticulous surface treatment to achieve a near-perfect finish. We pay close attention to both the surface appearance and the edges, ensuring that they are smooth, well-matched, and visually appealing. Our commitment to quality extends to every aspect of the cargo lift, including its overall outlook.

Platform lock and hinge

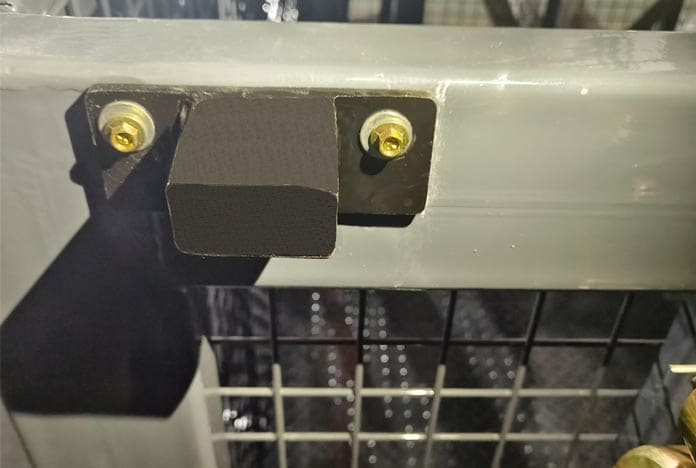

Limit switch touch block

8.The installation

How many parts are already assembled in warehouse cargo lift factory?

At XYZLift, we understand the importance of a smooth and efficient installation process for your warehouse cargo lift. That’s why we take pride in our pre-assembly capabilities, ensuring that many key components are already put together before the lift reaches your facility. Here’s an overview of the pre-assembled parts:

Main Components: Our expert team assembles essential cargo lift parts in our factory, including the chain, rope, cylinder, and lifting frame. These critical elements are carefully integrated to ensure optimal performance and reliability.

Platform Assembly: The cargo lift platform is fully assembled in our factory, saving you valuable time and effort. Once delivered, there is no need for additional work on the platform itself.

Guardrail Rails: The guardrail, an important safety feature, is the only component that requires customer assembly. We cut the guardrail into two parts that fit over the lifting frame. Customers simply need to assemble the smaller guardrail rail upon installation.

Electric Box and Motor: The electric box and motor are crucial components that require attention during installation. Our team ensures that the hydraulic oil pipe is properly connected to the pump station, and all electric wires are already connected. Customers are responsible for fixing the limited switch, a straightforward task.

Streamlined Installation: With approximately 90% of the installation work already completed in our XYZLift warehouse cargo lift factory, your installation process is significantly simplified. We aim to minimize on-site assembly time, allowing you to start using your cargo lift efficiently and promptly.

By providing pre-assembled components and streamlining the installation process, XYZLift ensures a seamless experience for our customers. You can trust that our cargo lifts are meticulously prepared for easy installation, saving you time and effort in integrating the lift into your warehouse operations.

9.Rust Removal and Spray Coating: Protecting Your Cargo Lift Investment

At XYZLift, we prioritize the quality and durability of our cargo lifts. To ensure their longevity and resistance to rust, we employ a meticulous rust removal and spray coating process. Here’s an overview of our approach:

Rust Removal: We utilize shot blasting, a highly effective method for removing rust from the steel surfaces of the cargo lift. This process thoroughly cleans the metal, eliminating any existing rust and creating a smooth surface for the next step.

Surface Preparation: Following the rust removal process, we take special care to clear the cargo lift surface of any residual blasting sand. This step ensures a clean and pristine surface, free from any debris or contaminants.

High-Temperature Baking Paint: After surface preparation, we apply a high-temperature baking paint to the cargo lift. This paint provides exceptional protection against rust formation and enhances the overall aesthetics of the lift. We take pride in our attention to detail during the painting process, ensuring a flawless finish that meets our stringent quality standards.

Customized Color: At XYZLift, we understand the importance of aesthetics and branding for your cargo lift. That’s why we offer customization options for the color of the lift. Simply provide us with the RAL number corresponding to your desired color, and we will produce the cargo lift accordingly.

By prioritizing rust removal and employing a high-quality spray coating process, we ensure that your cargo lift is well-protected and visually appealing. Our commitment to surface treatment reflects our dedication to delivering a product that not only functions flawlessly but also stands the test of time.

Steel after rust remove

High-temperature baking paint

10.Cargo lift with or without the mesh enclosed

The mesh enclosure plays a vital role in ensuring the safety of individuals near the cargo lift, particularly during its operation. However, the decision to include a mesh enclosure depends on your budgetary considerations. Let’s delve into this further:

Enhancing Safety: A cargo lift equipped with a mesh enclosure provides an additional layer of security by preventing unauthorized access and keeping personnel at a safe distance from the operating lift. It acts as a physical barrier, minimizing the risk of accidents and ensuring a controlled environment during lift operations.

Budget Considerations: We understand that budget constraints may influence your decision. While a mesh enclosure enhances safety, it is important to consider your specific requirements and allocate resources accordingly. XYZLift offers both options—cargo lifts with and without mesh enclosures—allowing you to choose the configuration that aligns with your budget and safety priorities.

By evaluating your budget and safety needs, you can determine whether investing in a cargo lift with a mesh enclosure is the right choice for your warehouse. XYZLift is dedicated to providing tailored solutions that meet your budgetary requirements while prioritizing safety and functionality.

11.Cargo lift will be fixed on ground directly or in the pit?

When considering the installation of a cargo lift, you have two main options: fixing it directly on the ground or installing it in a pit. Let’s explore these choices in more detail:

Ground Fixing: If you opt for ground fixing, XYZLift will provide a ramp with a thickness of approximately 150mm. This allows for a smooth transition between the lift platform and the warehouse floor. Ground fixing is an excellent choice when your warehouse does not have the capability to accommodate a pit.

Pit Installation: In cases where your warehouse floor allows for a pit, XYZLift will supply a pit of suitable dimensions. With a pit installation, the lift platform and the ground floor will align at the same level. This configuration offers seamless cargo entrance and exit, making it an ideal choice for efficient operations.

By considering your specific warehouse layout and requirements, you can determine whether ground fixing or pit installation is the most suitable option for your cargo lift. XYZLift is committed to providing the necessary guidance and support to ensure a successful installation tailored to your needs.

On ground with ramp

Fixed in pit