What is a Dock Leveler

What is a Dock Leveler?

A dock leveler is a vital piece of loading dock equipment that creates a safe, seamless bridge between your warehouse floor and a truck or trailer. It is designed for the efficient movement of forklifts and goods during loading and unloading.

Key Benefits of Dock Levelers:

Improves Safety: Prevents accidents and creates a stable surface for equipment.

Increases Efficiency: Speeds up the loading/unloading process.

Versatile: Compensates for different truck bed heights.

Main Types of Dock Levelers:

Hydraulic Dock Levelers: Use hydraulic cylinders for smooth, powerful, and easy operation.

Mechanical Dock Levelers: A cost-effective solution that uses springs and levers.

Air-Powered Dock Levelers: Utilize airbags for efficient operation where air supply is available.

These devices are fundamental for warehouses, distribution centers, and any facility with a loading dock, ensuring a safer and more productive workflow.

Different Dock Leveler

Our Models of Dock Leveler

| MODEL | LOAD CAPACITY (T) | PLATFORM SIZE (MM) | POWER (v/kw) |

|---|---|---|---|

| XYZCP-6 | 6 | 2500*2000*600 | 380/0.75 |

| XYZCP-8 | 8 | 2500*2000*600 | 380/0.75 |

| XYZCP-10 | 10 | 2500*2000*600 | 380/0.75 |

Platform size,load capacity could be customsized.

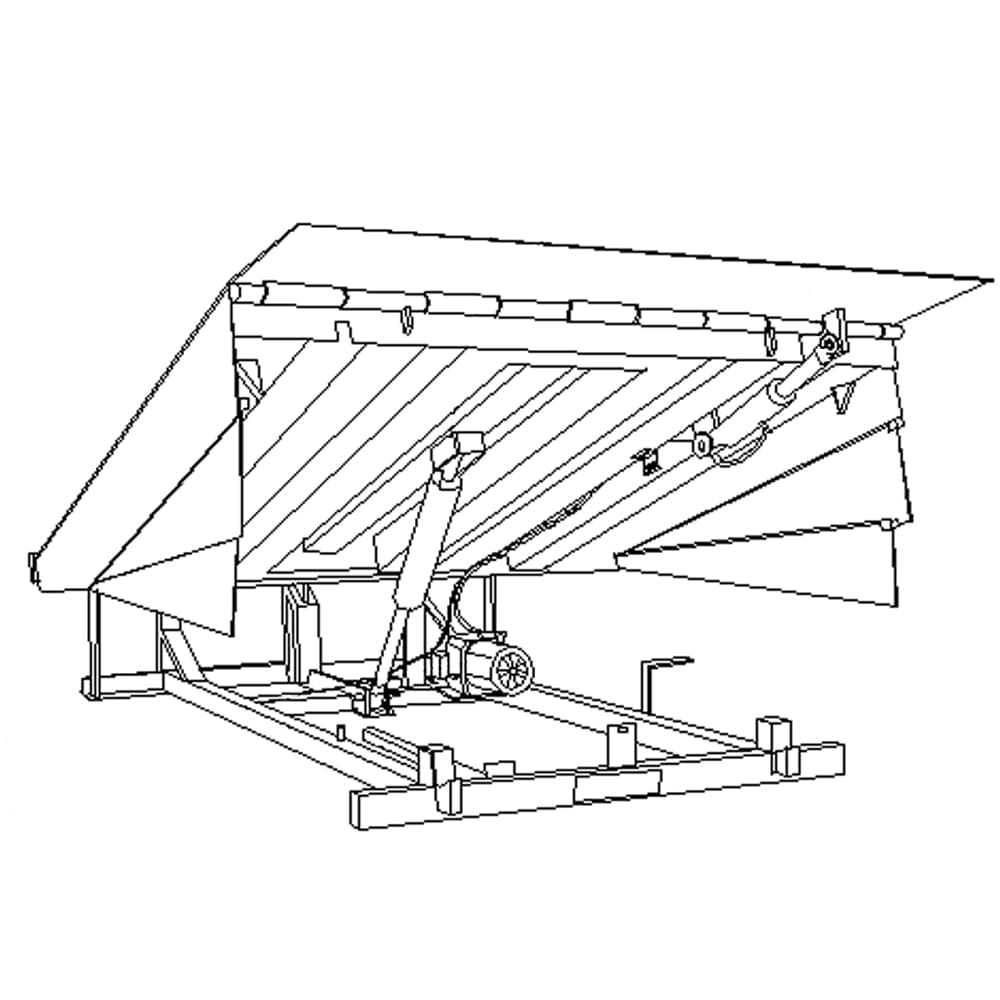

Major Components for Dock Leveler

By tongue plate, panel, bottom frame, skirt plate, support foot, large plate oil cylinder, tongue oil cylinder, electric control box, hydraulic station, maintenance support, anti-collision block

Tongue Plate

1 of 8 2Panel

2 of 8 3Bottom Frame

3 of 8 4Skirt Plate

4 of 8 5Support Foot

5 of 8 6Large Plate Oil Cylinder

6 of 8 7Tongue Oil Cylinder

7 of 8 8Pumping station

8 of 81

Tongue Plate

The tongue plate of a dock leveler serves as the crucial bridge between trucks and the dock leveler during the loading and unloading of cargo.When a truck is positioned at the loading dock, the tongue plate extends from the dock leveler to connect with the truck bed. This connection forms a secure and stable link, allowing forklifts or other material handling equipment to smoothly move between the dock and the truck.

2

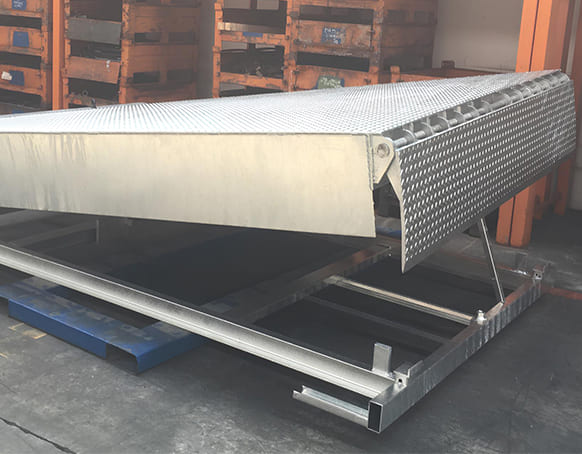

Panel

The dock panel of a dock leveler serves as an anti-skid plate, providing a secure and slip-resistant surface for loading and unloading operations. Its design and specifications are determined based on the load capacity requirements of the dock leveler.The base structure of the dock panel is carefully designed to ensure it can withstand the anticipated load capacity. The structural components are engineered to provide sufficient strength and support, guaranteeing safe and reliable performance during cargo transfers.

3

Bottom Frame

Our dock levelers feature a robust bottom frame constructed from carefully selected rectangular steel tubes. The size of the frame is customized based on the load capacity and platform size, ensuring exceptional support and stability. We prioritize structural integrity and durability, utilizing thicker and stronger steel tubes for higher load capacities. With our high-quality dock levelers, you can expect reliable performance and longevity. Contact us today to explore our range of dock levelers and discover the ideal solution for your business

4

Skirt Plate

The skirt plates are securely attached to the sides of the dock leveler, extending downward to cover the open area beneath the platform. They act as a visual reminder and physical deterrent, ensuring that individuals remain in the safe designated areas while the dock leveler is in use.

5

Support Foot

The support foot is designed to provide additional stability and support, specifically during maintenance procedures.When maintenance or servicing is required, the support foot is engaged to provide a solid base for the dock leveler. It acts as a safety support, preventing any unintentional movement or instability while personnel are working on or around the equipment.

6

Large Plate Oil Cylinder

We e prioritize efficiency and reliability in our dock levelers. The Large Plate Oil Cylinder is carefully selected and engineered to ensure it can handle the anticipated load capacity with ease. By providing the appropriate size of the oil cylinder, we guarantee optimal performance and safety during the lifting operation。

7

Tongue Oil Cylinder

The Tongue Oil Cylinder is responsible for lifting the tongue plate of the dock leveler up and down, ensuring that it aligns with the truck at the correct position.

8

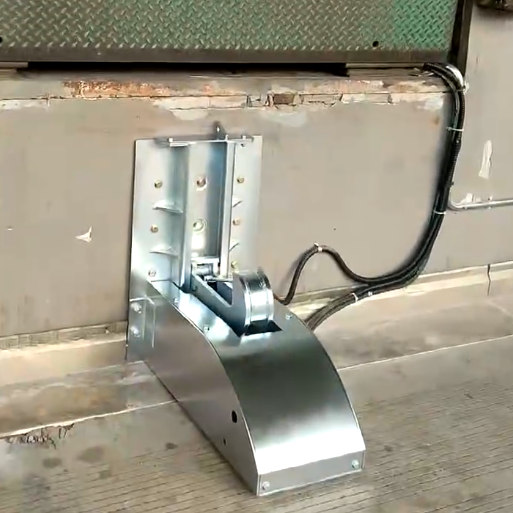

Pumping station

The pumping station of our dock leveler is designed with a power capacity that aligns with the load capacity of the dock leveler. This ensures optimal performance and efficiency during operation. Additionally, our pumping station is equipped with a motor that includes an emergency decline feature. In the event of a power failure, the emergency decline allows for controlled lowering of the dock leveler, ensuring safe and reliable operation even without a power source.

Standard Configuration

Not found what you are looking for?

We could still help! Contact our team to find out more.

Optional Dock Leveler

Enhanced outdoor rust resistance capabilities.

Door shelter could be inflatable type and sponge type

Anchoring kit prevent truck move when loading/unloading cargo.

Applications for Dock Leveler

See Dock Leveler Working

Operation & Maintenance

If you encounter any problems while using our dock levelers, our experienced after-sales team will assist you in resolving them quickly.

Safety instructions posted next to dock leveller control buttons for secure machine operation.

before operate goods lift, ready operation giuideline to operate dock leveller on right way

We provide a detailed daily maintenance checklist to ensure proper upkeep of the dock leveller.

Most Frequently Questions.

The delivery time for our goods lifts is 3–5 days from the order deposit. Dock leveller we have stock for standard size.

To accurately specify a dock leveller, we require the following information:Load capacity: Weight and type of materials and forklift to be lifted

Platform size: Size slightly larger than the materials being lifted.

Motor is produced according to customer local voltage.

Our heavy-duty dock leveller can lift items weighing up to 100 tons.

Enhanced Efficiency: Dock levelers streamline the loading and unloading process, allowing forklifts and material handling equipment to move smoothly between the dock and trucks. This improves productivity and reduces downtime.

Improved Safety: Dock levelers are designed with safety features such as lip extension plates, safety locks, and sturdy construction to ensure secure operations and prevent accidents or injuries during loading and unloading.

Customizable Options: Dock levelers can be customized to meet your specific requirements, including load capacity, platform size, and lifting mechanisms. This ensures that the dock leveler fits your unique operational needs.

Durability and Longevity: High-quality dock levelers are built to withstand heavy usage and harsh environments, ensuring long-term durability and minimizing maintenance requirements.

Cost Savings: Efficient loading and unloading processes with dock levelers result in time savings, improved labor productivity, and reduced product damage. This leads to cost savings in the long run.

Versatility: Dock levelers can be used in various commercial and industrial settings, including warehouses, distribution centers, manufacturing facilities, and more, making them a versatile solution for different applications.

Custom Lifts That Suits Your Need

You will get accurate lift solution in 24 hours.Please supply main information as follows

- Platform size

- Load capacity