Customer Background and Abnormal Noise of Cargo Lift Guide Rails

Our after-sales engineer, Jason, received a call from the HARLEY-DAVIDSON SHOP customer, who reported abnormal noise when their elevator was in operation. They purchased a freight elevator in 2021 for transporting motorcycles between the first and second floors. The specifications are as follows:

| Load capacity | 2000kgs |

|---|---|

| Lift height | 4m |

| Platform size | 3x1.8m |

| Silent Motor | 4kw, 30dB |

After receiving the customer’s feedback, our technical team gathered the customer’s purchase order, parameter configuration, professional tools, and arrived at the HARLEY-DAVIDSON shop within an hour.

As shown in the video, there was a strange noise.

Cause Analysis and Solution Process

The after-sales personnel first performed the following actions:

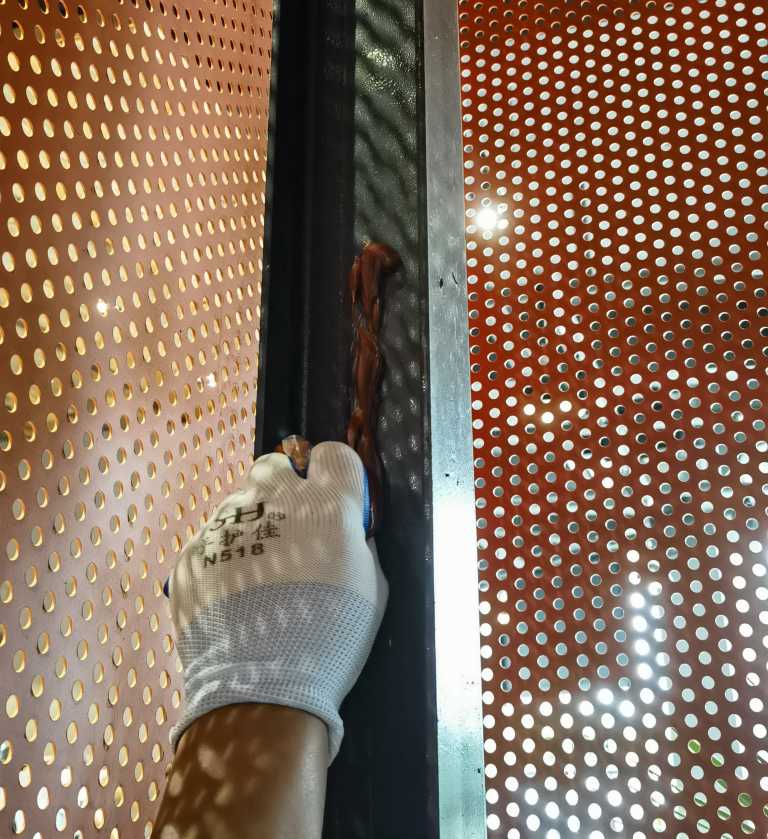

- Applying grease to the guide rails

Tools: Grease, gloves

We purchased industrial grease suitable for the guide rails of the cargo lift platform.

Specific operation method:

Apply grease to the inner side of the four guide rails on the first floor, and perform two up and down movements.

Perform the same action on the inner side of the four guide rails on the second floor.

After lubrication, the noise during the platform’s operation on the first floor disappeared. However, when the cargo lift platform passed through the middle position of the second floor, it still made abnormal noise. After repeated testing, the engineer determined that the noise was caused by the tightness of one of the guide rail rollers. The roller misalignment was due to uneven tension in the four chains caused by uneven loading.

- Adjusting the chains, tightening one end and loosening the other end.

Tools: Wrench

Analysis of the Cargo Lift Rail Noise

- The rail had not been maintained for a long time, approximately three years.

- Long-term uneven loading.

Conclusion:

- Regular maintenance is required for daily use.

- Pay attention to avoiding uneven loading and ensure that the goods are placed in the center.

Other Common Cargo Lift Abnormal Noises

During the operation of hydraulic cargo lift, abnormal noises may occur due to various reasons. Based on our practical experience and technical analysis, the causes of abnormal noises and increased noise level in hydraulic elevators can be roughly divided into the following categories:

- Noises caused by electrical equipment or components failures in the hydraulic elevator:

– Low voltage and current, mismatched projects leading to motor reversal. Countermeasures: Increase current and match voltage appropriately.

– AC contactors in the distribution box fail to engage during startup, resulting in frequent contact between the movable and static contacts, producing abnormal noises. Causes: Voltage mismatch, use of cables with insufficient diameter resulting in low current that does not meet design requirements. Countermeasures: Choose suitable equipment voltage and current according to the instructions.

– Motor humming noise caused by damaged motor bearings, resulting in friction between the stator and rotor. Countermeasures: Repair the motor.

– Overloading, exceeding the rated load, causing excessive strain. Countermeasures: Unload the elevator to a load below the specified limit in the instruction manual.

- Failures in the hydraulic system of the cargo lift:

– If the cargo lift abnormal noise occurs at the power unit, it may be due to blockage at the oil outlet, leading to poor oil flow. Countermeasures: Let the motor run for a period of time until the oil temperature rises, then clean the blocked area and refill with high-quality hydraulic oil.

– If the abnormal noise occurs at the cylinder, it may be due to increased clearance between the piston rod and cylinder caused by machining errors. Countermeasures: Contact the manufacturer for assistance.

- Noises generated by the main structure of the hydraulic elevator:

– Severe wear or poor surface smoothness of the rollers on the upper and lower platforms of the lifting mechanism, resulting in loud noises during their movement in the guide slots. Countermeasures: Replace qualified rollers; if the guide slot surface is rough, it can be treated to improve smoothness.

– Lack of lubricating oil in the sleeve or shaft connected to the scissor support rod, resulting in increased noise during platform lifting. Countermeasures: Apply lubricating oil.

– Loose bolts of the lifting platform, causing shaking and noise during the lifting process. Countermeasures: Inspect and tighten the bolts.

In conclusion, the abnormal noise of cargo lift guide rails may be caused by long-term lack of maintenance, uneven loading, hydraulic system failures, or structural issues. To solve these problems, regular maintenance of the guide rails is necessary, and attention should be paid to avoiding uneven loading. The hydraulic system should be inspected and repaired, and the bolts should be checked and tightened. These actions can effectively reduce the abnormal noise of elevator guide rails and ensure their normal operation.