Hey there! If you’ve ever wondered about the pricing of goods lifts and what goes into it, you’re in the right place. I’m a sales engineer with over 12 years in the hydraulic lift industry, and today, I’m here to share some industry insights. These come from my extensive experience with over 300 client transactions, 100+ pre-shipment inspections, and numerous after-sales issues.

Let’s dive into the 10 key factors that influence the cost of goods lifts:

1. Capacity

The load capacity dictates the power of the motor and the specifications of the hydraulic cylinder. Naturally, a higher load capacity means a more powerful motor and larger cylinder diameter, which in turn, increase the cost.

2. Travel Height and Stops

- – Higher travel heights require longer guide rails, chains, steel cables, and hydraulic cylinders.

- – More stops on the lift necessitate additional sensor switches, adding to the complexity and cost.

3. Platform Size

- – The size of the platform affects the number of guide rails and cylinders needed.

- – Standard safety rail heights are 1.1 meters; anything taller increases the cost.

This is a 2.2-meter high guardrail with solid sides made of 1.2mm thick steel plate, galvanized and coated, extending to the platform. Bumpers are installed on the internal sides of the platform at floor level, 600mm, and 1200mm. Requested by an Australia Client.

4. Speed

- Our standard lift speed is 5 meters per minute. If a faster speed is needed, say up to 15 meters per minute, a larger motor is required, increasing costs

5. Pit Requirements

- If the installation site has a pit, a ramp is not necessary. Otherwise, a ramp must be constructed at the front of the platform.

6. Full Enclosure

- Mesh type: Standard sizes are 50x50mm or 40x40mm.

- Plate type: Options include full metal or perforated metal sheets.

7. Landing Doors

- Material options include mesh doors, roll-up doors, automatic doors, and fireproof doors.

- Roll-up doors can be made from PVC or aluminum, and the speed at which they open can also affect the price.

We have summarized the choices for common landing doors, please see this article.

8. Motor Specifications

- Brand and power can significantly influence cost. Options range from local Chinese brands to international ones like Siemens and SEW, with SEW generally being the most expensive. Delivery times also vary, with SEW taking up to two months for orders under five units.

- Voltage requirements such as 208V 60Hz can also lead to a price increase.

- A standard protective casing for the motor is included, but if it’s not needed, removing it can reduce costs.

9. Electrical Control System

- Our standard is a Chinese control box, chosen by 95% of our customers.

- European and Australian standards are available for regions with stringent acceptance requirements, featuring local electrical standards to facilitate faster approval.

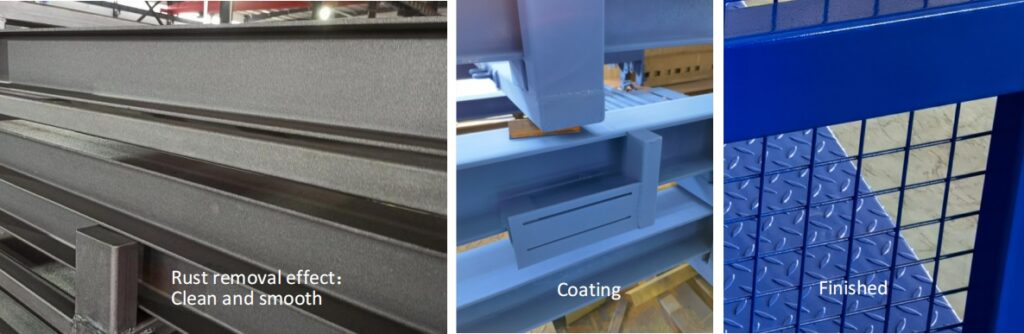

10. Surface Treatment

- Standard treatment involves shot blasting and powder coating. However, galvanizing or electrophoresis is recommended for corrosive or humid environments, such as seaside locations, increasing the cost.

Shot blasting and powder coating

Galvanizing

Electrophoresis

Beyond these common factors, some clients require additional features like explosion-proof designs, insulation standards compliance, or platform weighing capabilities. Each special feature can significantly impact the overall cost of a goods lift.

Understanding these factors will help you grasp the complexities behind goods lift pricing and why costs can vary so widely. Whether you’re buying a lift or just curious about the technology, knowing these details ensures you’re well-informed.